First off, the disclaimer. The information in this article is for education only and is in no way a recommendation on reloading practices. For any reloading information and powder selection, refer to published reloading manuals or powder manufacturer specifications.

Also, I will have a supplemental YouTube video soon for people who are like me and would rather watch a video than read an article. I will add that to the bottom of this post when it is done.

To anyone wanting to get started into reloading, it can be very intimidating. All the different bullet options, bullet weight, powder brands, and powder burn rates can be enough to scare people away from starting. So before the technical dive here are some basics. Reloading is typically done for two main reasons. Either to mass produce target ammo cheaper than you can buy it, or get the most accuracy out of your firearm as possible. I’m going to focus on the latter.

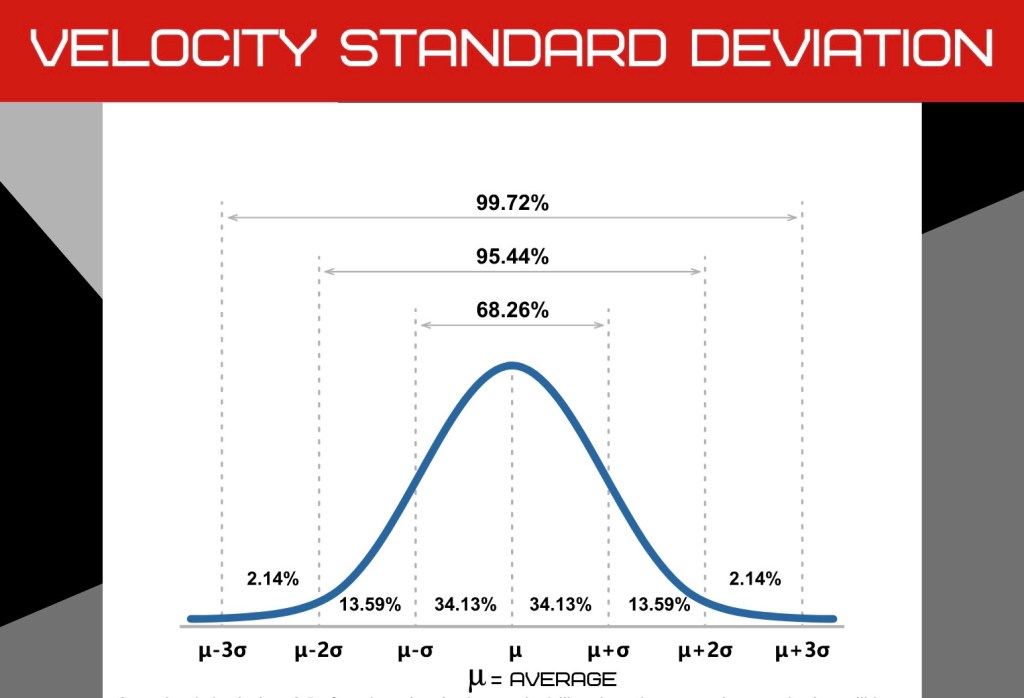

The main benefit to reloading for accuracy is consistency. Factory ammo has come along way with some great options that I have had good success with, but there is always inconsistencies in mass production. Reloading allows you to be as picky as you want to be and control every component. You have much better control on bullet seating depth and how much powder you are using. If you are hesitant about starting to reload I would say get the components, a good reloading manual that has the round you want to load for, and reload to a spec in the book. Try a few different published options with different bullets and powders, and see how they effect things like group size. You don’t need to worry about making your own load, but you will be able to learn and get a feel for how to make your loads consistent. When you get comfortable you can start playing around and find out what works and you can start to “tune” loads to your rifle. I’m done rambling now, so lets get back to what this article is for, a technical discussion on powder burn rates.

First off, the powder composition. Modern smokeless powders are typically nitrocellulose based. Manufacturers add in different additives to do things such as modify burn rate, increase temperature stability, and decrease fouling. This is what differentiates all the different powders they manufacturer. There are also a few common shapes of powder grain you will see: spherical powder (round balls), disk powder (just like it sounds), or rod (in varying lengths and diameters). Along with composition, shape also has an effect on burn rate. The more surface area available, the more of that powder grain is burning. *Side note, do not confuse an individual powder grain with the measurement unit of grains. Powder is usually measured in grains, but a grain in this sense means 1/7000th of a pound, not individual pieces of powder*. Now because chemistry is not my expertise, we will leave it at that and know that powder manufacturers make a plethora of different powders and burn rates for different applications. Now lets look at how different burn rates can effect a load.

Burn rate and powder weight has a direct effect on chamber pressure and this is what dictates the burn rate to use for your cartridge. Each round has its own established max pressure. Burn rates are also relative, what is fast for one round may be slow for another round. It can also vary for the same round using different bullet weights. a lighter bullet can typically use a faster powder than a heavy bullet in the same cartridge.

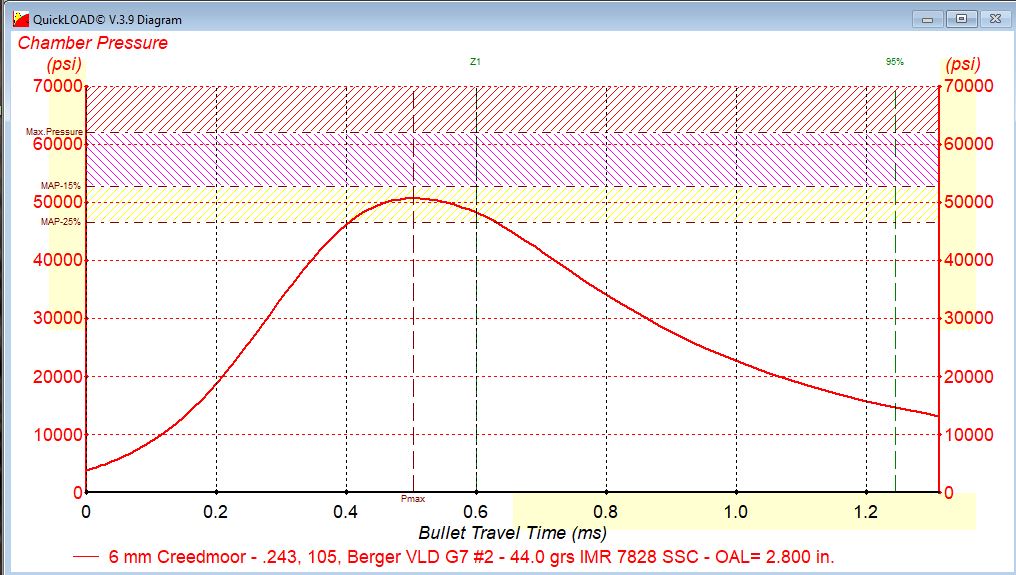

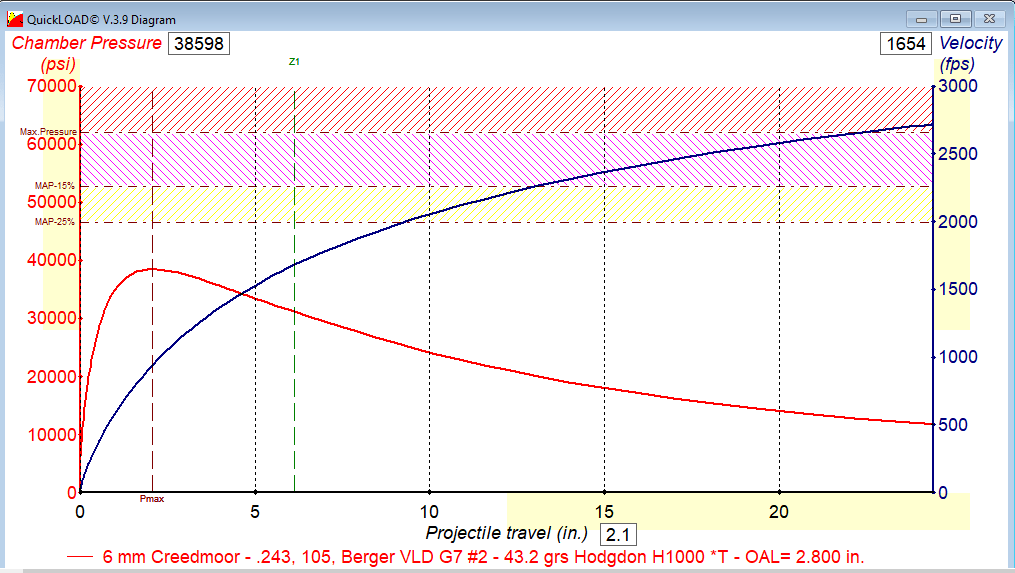

Below is the pressure curve of my current load vs. time. This was taken from the QuickLOAD reloading software that estimates pressure and velocity for custom load information. A few key things to note that we will compare are: powder type, powder weight in grains (grs), peak pressure, and the green vertical line indicating 95% of powder burned.

Lets break down this chart. At time 0, the primer is ignited. This creates an initial bump in heat and pressure that starts the powder burning. The powder burns and builds pressure until it peaks at the max pressure. After that point the pressure reduces until finally the bullet leaves the barrel. Below is the corresponding bullet velocity.

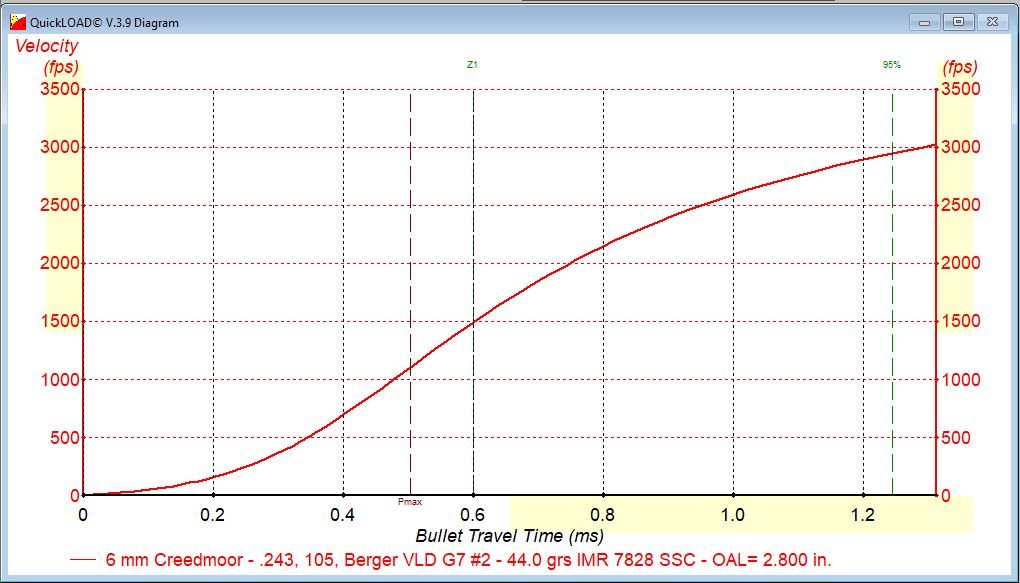

Since pressure is related to the available volume, case volume and how far this bullet is down the barrel effects chamber pressure. The bullet is compressed in the case neck under tension and needs an initial bump to start pushing down the barrel (heavier bullets also need a higher pressure to start moving because of more mass). From the graph, bullet velocity begins to build and the acceleration increases until it reaches Pmax. After that point, the bullet is still accelerating, but not as quickly. The slope of the graph at any point is the acceleration. Below is a graph of pressure and velocity by bullet distance down the barrel.

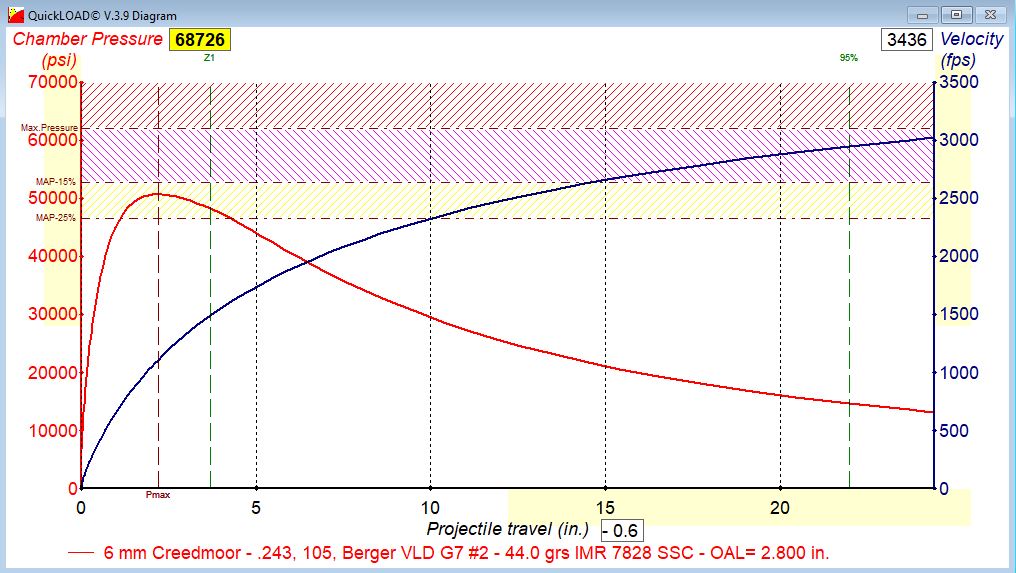

using IMR 7828 powder. Ignore the pressure and velocity listed at the top, that is where my cursor was during the screen shot.

Here you can see the pressure spikes rather quickly within the first three inches of bullet travel. And since higher pressure equals higher force, the bullet accelerates faster when the pressure is higher. But you can see, that the muzzle pressure with this load is still around 10,000 PSI and not all of the powder has been burnt. Lets compare this to a much faster burn rate powder.

using H335 powder

I was trying to get roughly the same peak pressure, so you can see that the powder in the first graph used 44 grains. this powder only uses 34.9 grains. Faster burn rates mean reaching peak pressure with less powder because it is burning and converting to heat and gas quicker. As a general rule, to get the same peak pressure you need less of a faster powder and more of a slower powder. You can also see the location on the chart showing “all burnt” that is the where all the powder is consumed. At this point, no pressure is being created and you are going off the remaining internal pressure already created. This still gives a muzzle pressure of roughly 8500 PSI, but muzzle velocity has dropped from around 3050 fps to 2800 fps. Even though the max pressure is roughly the same, the faster powder burned too quickly and was not able to keep maintaining pressure to offset the increase in volume as the bullet travels down the barrel, leading to a much lower muzzle velocity.

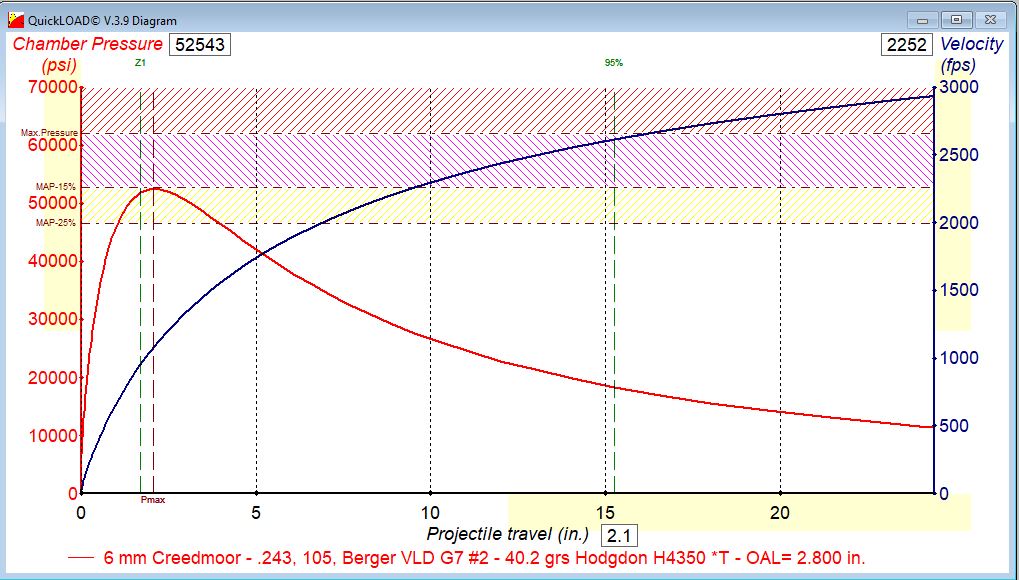

Here is one more to look at. This powder has a burn rate in between the two above. The velocity isn’t quite as fast, bust is much closer to 3000 fps. The 95% burn line is also earlier, the powder isn’t completely burnt, but more is burned that the first graph so you are wasting less powder. The muzzle pressure is also slightly lower than the first. Higher muzzle pressure and unburnt powder lead to a larger muzzle blast, and increased muzzle flash, in some instances this may matter.

using H4350 powder

Let’s look back over those and look at the shape of the pressure curve. slowest powder has a more drawn out peak rather than a spike and drop. It tapers slower after the peak pressure because the powder is still progressively burning, shown by the Z1 line. The burn is accelerating but the bullet moving is changing the volume to keep the pressure maintained. On the faster powders, the Z1 line is before the max point so there isn’t as much energy maintaining that pressure. This is why in this instance the slowest powder has the highest velocity, it is able to maintain a higher pressure for longer. leading to more force and acceleration on the bullet.

For reference, lets look at using a powder that is too slow for the application. this is using 43.2 grains for H1000. The problem here is that at this point the case is at 100% capacity. The powder burns too slow with the available volume to reach a high pressure.

Back to what I said before, burn rates are relative to the cartridge and bullet weight they are used for. H335 powder is way too fast for a 105 grain bullet 6mm creedmoor, but is a good powder to for something like a 68 grain bullet 223. But a similar trend will follow for different cartridges based on a powder being too fast or slow for the application. This is why it is important to consult reloading manuals. They have calculated pressures for different powders, cases, and bullet weights.

This was a little long winded so hopefully I didn’t miss anything or confuse anyone. If I did, leave a comment and let me know!

Leave a comment